|

Dirty-South Blues Harp forum: wail on! >

Lucky 13 a look inside

Lucky 13 a look inside

Page:

1

dchurch

46 posts

Oct 25, 2016

8:57 AM

|

I've had my Lucky 13 (A) for about a week. I love it!

Shipping was reasonably quick. The harp came well packaged and the overall impression is a quality product.

This extended Ricther was super easy for me to adjust to. Within just a few minutes I was able to put the low end to work. I was surprised by how easy it was to incorporate the low end and how much dimension I’ve been learning to create with it. Being a bit longer, hand cupping took some adjusting.

I'm very happy with the A harp. The low end is not for high volume but I like the deep bass sounds. I have a “low A” Seydel steel and the low end is very similar, but then the entire harp is low which can seem a bit stifling sometimes. This Lucky 13 has a very cool range.

My Lucky 13 played very well OTB. After a bit of playing I had no particular trouble with bends…

But as with all my new harps I still have to open things up and do some tweaking.

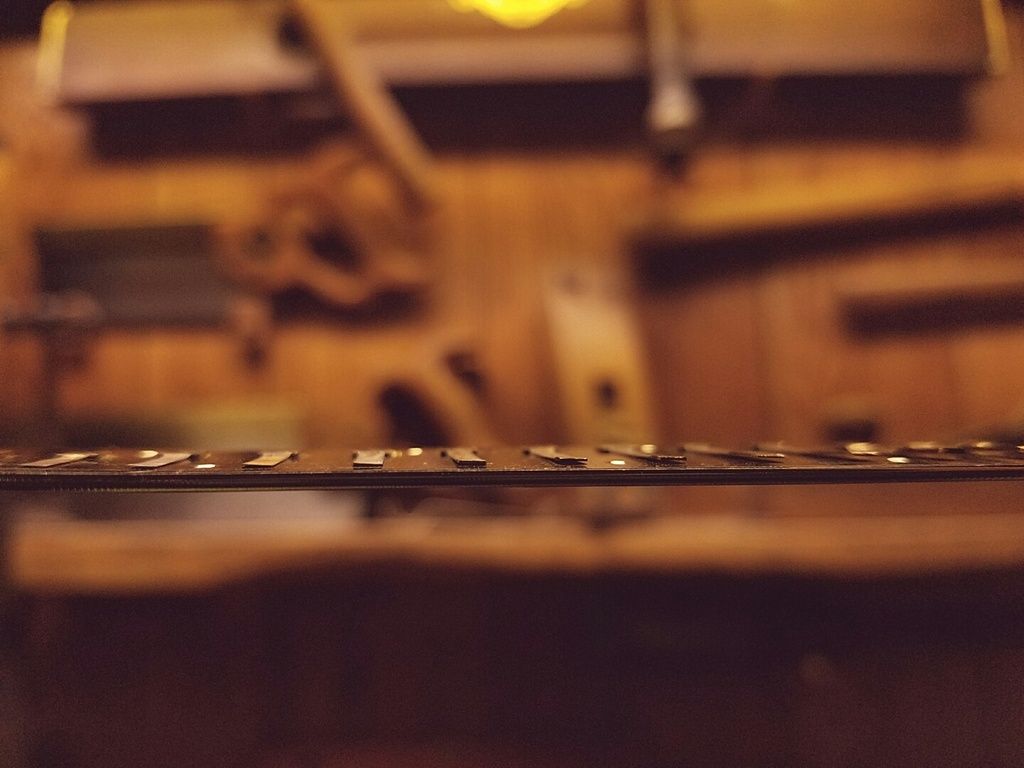

Here's a look inside:

The covers are fastened using two sex-bolts with standard Phillips heads. The reed plate screws are also standard Phillips head, so that’s the only tool needed.

The top and bottom reed plates are extremely well secured using 11 through screws.

A small metal support piece makes the covers crush proof.

The comb is a solid piece of what seems to be a non-brittle plastic. It has some degree of flexibility and a density closer to traditional pear-wood rather than Plexiglas.

The comb shows factory flattening marks from about 220 grit abrasive. I couldn't help myself and did a flat sanding with 320 through 1500 grit. That only took 2 or 3 minutes because the OTB comb was pretty flat and the material sands well. Nice comb!

The OTB reed plates are flat and precise. The reeds are well centered in the slots but not all were perfectly level or gapped. My L13 has some “superficial” unnecessary scratches on the plates.

The Lucky 13 uses welded reeds which is fine with me. When the time comes I replace welded reeds using screws.

I tweaked some of the gaps and called it good. This Lucky 13 plays as well as my other good quality harps (MB, Manji, Sessions, Lee Oscar…).

I play other tunings and I'm thinking about changing the 7-10 on this one. That would be cool too.

----------

It's about time I got around to this.

Last Edited by dchurch on Oct 25, 2016 9:13 AM

|

florida-trader

1020 posts

Oct 25, 2016

9:24 AM

|

Nice review. It could be an optical illusion but it looks like some of the reeds could have a curve in them (tip raised a bit) and are slightly twisted. Many of the Hohner reeds look like they are twisted at the tip but upon closer inspection it is an illusion created by whoever did the tuning filing material off only one side of the reed tip. But by all reports, it seems like East Top has made their mark in the harmonica world and will be a force to be reckoned with.

----------

Tom Halchak

www.BlueMoonHarmonicas.com

|

Gnarly

1968 posts

Oct 25, 2016

9:28 AM

|

The reed material is hard, much harder than the phosphor bronze that Suzuki uses.

I retuned a C to solo tuning, it's mostly done (letting it sit and will check the tuning to ship on Friday), but I got a chance to raise a few reeds 4 and 5 half step. Gnarly!

|

dchurch

48 posts

Oct 25, 2016

11:29 AM

|

Tom,

Yes, OTB some of the reeds are not perfect... the head on photo of the reeds is pretty accurate. I did not find any off filed reed tips but a couple of top leading edges were nicked during tuning. I normally stay away from the very tip. Anyway, the harp played fine for me OTB. Keep in mind, it’s just one harp. It honestly didn’t play remarkably better or worse than what I normally get from other harps. I did tweak this harp to my liking so naturally it plays even better now.

I do not own any other East Top harps but I am very happy with this one.

----------

It's about time I got around to this.

|

mlefree

783 posts

Oct 26, 2016

9:30 AM

|

Uh oh. Welded reeds...

Michelle

----------

SilverWing Leather - Custom leather creations for musicians and other eccentrics.

|

Brendan Power

531 posts

Oct 27, 2016

1:35 AM

|

Michelle: welded reeds should be no bother for a tech-minded person such as yourself. If you can do that beautiful leatherwork, then replacing a welded reed is a doddle!

There are two main ways: Use the Suzuki tool, or basic workshop tools.

Suzuki have created an elegant punch-and-screw set for the replacing welded reeds, the HRT-10. It's smart, easy to use, and will work on other brands with welded reeds. Here is the instructional video:

https://www.youtube.com/watch?v=GS9zo4KaN20

If you don't want to shell out for the Suzuki kit, there is no need! Here's an old video I did showing how to do it with basic home workshop tools:

https://www.youtube.com/watch?v=kChMKU7LEVo

I did a couple of others for chromatic harmonicas.

The Suzuki screws are not easy to find, but Richard Sleigh pointed me to this excellent alternative, M1.4 x 2 cellphone screws:

http://www.ebay.com/itm/100-Cell-Phone-Screw-M1-4x2mm-Micro-Screws-Repair-Mini-/260693687350?hash=item3cb28dfc36:g:r6QAAOxyUXVRCMYh

Have a go Michelle, it's actually an enjoyable and very satisfying experience! Once someone actually does this for themselves they find there is nothing to be worried about with welded reeds in terms of repairing your harps.

|

Rubes

1003 posts

Oct 27, 2016

3:03 AM

|

Hey dchurch yes good review! Where is the cheesy Lucky 13 logo? Looks like a decent harp....oh dear..I've just ordered two. :)

----------

Old Man Rubes at Reverbnation

Dads in Space at Reverbnation

|

mlefree

784 posts

Oct 27, 2016

11:50 AM

|

Brendan, I do a lot of tech work on my own and other's harmonicas. I have actually replaced welded reeds, guided in large part by your excellent tutorial videos that you shared on Youtube. And, I agree it's not that difficult for a technically-minded person who is well equipped (I do mine without the Suzuki tool). But, frankly there is also always the issue of sourcing the donor or replacement reeds themselves.

Realizing that I've contributed to the (somewhat misguided) general fear and trepidation about replacing welded reeds here, I do think it's worth mentioning in a thread devoted to the innards of the Lucky 13s. It is a factor worth considering in the decision making process of potential buyers. Plus, in another thread I pointed out that Hohner SBSs are now out of production and that you could buy two Lucky 13s for the price of one of Seydel's steel reed Solist Pro 12-hole harps, the only other production harmonica featuring the revered "SBS" tuning. So I say buy two Lucky 13s and you'll not only have a backup, you'll have a source of replacement reeds in the event that a reed ever goes south in one.

(And thanks for the nice complement!)

Michelle

----------

SilverWing Leather - Custom leather creations for musicians and other eccentrics.

|

mlefree

785 posts

Oct 27, 2016

11:53 AM

|

dchurch, those are quite possibly the finest photographs of the innards of any harmonica I've ever witnessed. Anywhere.

Kudos (and thank you)!

Michelle

----------

SilverWing Leather - Custom leather creations for musicians and other eccentrics.

|

MindTheGap

1844 posts

Oct 27, 2016

12:28 PM

|

I recognise that twist in the reeds from my Easttop T004. At first I thought it was an error in one or two that would need correcting, but looking closer they all had the same twist. It responds really well, so maybe it's a new thing. Or maybe it's an unintended result of some part of the manufacture. Doesn't matter which, if it plays well.

I can't help but feel that the phosphor-bronze reeds ought to last for AGES longer than brass reeds, surely? No evidence for this, but it just seems like the right material for the job.

Last Edited by MindTheGap on Oct 27, 2016 12:59 PM

|

isaacullah

3231 posts

Oct 27, 2016

3:46 PM

|

Cool photos! I haven't had the time yet to crack mine open, so it's good to get a "sneak peak" of what I'll find inside. Looks like a quick high-grit flat sand on the combs, and some basic gapping is all I will need to do. Sweet! I don't have time for much else these days anyway.

@gnarly, I think the 'curves' that you noticed are due to the barrel distortion from the camera lens. Looks like a wide-angle lens to me, with shots taken very close with close focus. If this was done with a cell phone camera (as many photos are, these days), this kind of barrel distortion is common. You can see it in pretty much any "selfie," and is why people think their chins look weird in those kinds of pictures, lol!

----------

YouTube! Soundcloud!

|

isaacullah

3232 posts

Oct 27, 2016

9:13 PM

|

Ok, I cracked one of mine open tonight. Yeah, basically same thoughts as in the op. Good quality inside! Comb is definitely abs. You can smell it when you sand it. It sands well, and I think it's one of the very finest OEM combs I've ever seen on a harp. Fits all of my expectations and then some. Other than a little more sanding to really buff that comb up, the harp only needed gapping. And after that, it plays really really really well. I'm really impressed with how much improvement i got fro. basic gapping, a little sanding, and carefully torqueing the reed plate screws just enough upon reassembly. One note: don't lose that cover plate stay. Covers this long really need that thing!

----------

YouTube! Soundcloud!

|

dchurch

50 posts

Oct 28, 2016

4:07 PM

|

I'm back,

I couldn’t refrain from retuning my Lucky 13.

The original tuning is fantastic and I always feel just a little bit guilty when hacking into a perfectly good harmonica or in this case a perfectly awesome harmonica. But, I just had to try the L13 with my semi-circular set up (see off topic at bottom).

So here’s a further look inside the workings of my Lucky 13:

I have a mix of riveted and welded reeds harps and have repaired, swap reeds… on at least half of them. The pros and cons of working on them is a wash IMO. But, I do like the end result of using screws for future reed access.

Some observations of the Lucky 13 during this work:

I really enjoyed working on this harp. It’s definitely a winner :)

-The plates are stout and well machined

-All of the reeds on this harp are dead center

-The alloy reeds are tough and have tenacious memory. This was evident during the drilling process, and it took some serious flexing to adjust gaps. I suspect these reeds will hold up exceptionally well.

Brandon’s youtube video on welded reed work is excellent, but then he makes everything look easy. I use common 1.4mm Phillips head screws. I use a tap secured in a draftsman’s lead holder to thread the screw holes. For me magnification (Optivisor) and great lighting is a huge help during this kind of work.

These are the tools I used for swapping welded reeds.

The only special tool not shown is a Praxxon roto tool, which is something similar to a Dremel. It can be used as a hand grinder/polisher or installed in a mini drill press accessory. The tiny drill bits are very common in the world of electronics, so are the screws. *The gold drill bit in this photo just represents a second required bit that is currently in the drill press.

The work went very well and the result exceeded my expectations.

Loudness:

The Lucky 13 sounds loud to me. The 4,5,6 can be down right ear piercing. But is it truly louder than my other harps?

I decided to run a test. First I played with three different sound meter apps on my android Galaxy 7. The apps responded the same so I picked my favorite which is oddly named “Sound Meter”. It displays minimum, average, and maximum decibels (db).

I ran the test at a distance of 36 inches from the meter in a quiet room. I tested over a dozen different harps: Marine Band, Golden Melody, Suzuki (Manji, Pro, Hammond), Seydel (Session Steel, Session Brass, 1847, Favorite), Lee Oscar, and the Lucky 13. This is a mix of stock and customized harps in various keys, all have been gapped and are in good condition.

I covered the phone’s screen (no cheating) then I picked a harp, warmed it up then repeatedly went for the biggest sound possible using the 4,5,6 blow and draw. This sound meter saves the peak reading. I noted the result for each harp.

All of the harps peaked between 86 db and 88 db except for the Lucky 13 it peaked at 89 db.

I ran the test again but without the screen blocked and this time I tried various holes and combinations on each harp. This time I managed to hit at least 87 db with every harp and I hit 89 db with one of my Manji’s and I consistently hit 89 db with the Lucky 13.

One or two decibels may not seem like much but it is actually at least 10% louder to the human ear because the scale is logarithmic (www.sengpielaudio.com). So my ears were not lying, my Lucky 13 is louder than my other harps on average.

I’m guessing the reason has to do with the specific alloy of the reeds and possibly the larger size of the L13’s body chamber.

Here’s the Lucky 13 with its new special tuning. I’m digging it.

The Lucky 13 is the best addition I’ve added to my arsenal in a loooong time. I definitely see more Lucky 13s in my future.

Regards,

Dave

Off topic - special tuning:

I’ve tried other tunings but I’ve stuck with Richter tuning and Circular tuning (Seydel Melody King). One day I came up with a combination of the two, my version of semi-circular. I simply swap the 7, 8, 9, 10 reeds and retune the 10 draw reed on the scale. I like it because it’s similar to my Circular harps without losing the majority of what I play on the Richter harp. The Lucky 13 fits really well this semi-circular tuning. I feel like I have twice the blues power :) I also build Richter 7 hole harps with the 7th reeds swapped (posted here somewhere).

----------

It's about time I got around to this.

|

HarveyHarp

735 posts

Oct 28, 2016

8:09 PM

|

Mr. Church, it sounds like you know what you're doing. Nice work and pics

----------

HarveyHarp

|

nacoran

9276 posts

Oct 28, 2016

10:32 PM

|

That looks like the same crush bar, more or less, that Huang Silvertones use. I took one apart once and the thing must have fallen out ten times when I was trying to put the thing back together.

Other than that it looks good though. I'd noticed that something was different on the back there in Isaac's review video, but I'd guessed on a different solution.

----------

Nate

Facebook

Thread Organizer (A list of all sorts of useful threads)

First Post- May 8, 2009

|

Brendan Power

532 posts

Oct 29, 2016

5:44 AM

|

@dchurch: Nice work! It's great to see players doing such extensive customisation on the Lucky 13 so soon after it has come out.

Might I suggest you post a video on your welded-reed replacement method? If your video filming is as high quality as your photography I'm sure it will help demystify the process for those out there who still find the thought of swapping welded reeds a bit daunting - not just for the Lucky 13 but for the increasing number of harps with them (Suzukis of course, but virtually all Chinese-made harps now also). I'll be happy to post it on the Lucky 13 Video page:

http://www.brendan-power.com/lucky13.php#lucky13CustVideos

@Michelle: You're right, it is affordable to use a second Lucky 13 as a source for reeds if they break on the original. That being said, I'm finding the Easttop phosphor bronze reeds very rugged on the harps they make for me: AsiaBend, Slide Diatonic and Lucky 13. I've had no busted reeds on mine despite months of bending notes every which way possible.

@isaculla: The Lucky 13 is a loud harp I agree. Not planned that way, but I think it's down to the slightly thicker reedplates needed for the extra length.

So happy most of you are enjoying these harps :-)

|

6SN7

670 posts

Oct 29, 2016

7:43 AM

|

I've never had great luck with special tuned/10+hole diatonics. They were fun at first but ended up in my sock drawer.

The Lucky 13 is the happy exception. I am having a ball with it. From a personal stand point, I find it responses best to TBing .

Great harp BP and for my thrift Yankee/Scottish friends, great value for the $$

|

Roverharp

53 posts

Oct 29, 2016

11:13 AM

|

@mlefree: With both welded and riveted reeds I find centering reeds a challenge. If I torque the screw enough to secure the reed it tends to twist off axis at the root. If I leave the reed centered I think the screw will come loose.

I'm getting better and have found some ways to mitigate this problem but welded reed present the additional problem that any travel of the bit as I drill out the plate and reed will mean a lot of time setting the donor reed to the new plate. Even a fraction of a millimeter seems to hurt the process. It's the one task I feel uncomfortable doing when working on my harps.

No matter. I still plan to re-tune my Luckies when they arrive.

As a side note specific to East Top harps - you may be thankful for welded reeds on the Lucky 13 compared to their riveted models. With all the buzz around the Lucky I also ordered a few of East Top's T008K ten hole model. It's rivets are in TIGHT. Unlike any harp I've opened up. I abandoned swapping reeds for a re-tune for fear of damaging the reed plate.

|

dchurch

52 posts

Oct 30, 2016

11:50 AM

|

I appreciate the comments and compliments. I will see what I can do with a how-to video. Naturally, it would have to be a reed swap or re-installation because I may not live long enough to wait until I crack one of these on the Lucky 13!!!

Roverharp, I have had stubborn reeds that want to keep shifting into the wrong spot. I can normally solve that problem by removing the reed and then smoothing the mating surfaces of the reed head and plate. Also, smooth the top surface of the reed head. Then just try again.

I guess another fix might involve a small dot of adhesive or varnish if you get things just right but not quite snug enough. But it's not something I do.

Over tightening can be the problem. Just “snug” works fine, try it. Test it by knocking the harp against your hand… I’ve never had a problem with reeds going out of alignment.

Also, it shouldn’t matter where the hole is centered if the reed was secured in its slot when the hole was drilled straight through both the reed and the plate. Again, both mating surface should be flat smooth during the drilling.

But, if for some reason the hole in the reed is preventing alignment just enlarge it using a bigger drill bit. For example, if you are using 1.4mm screws use a 1.6mm bit for drilling the reed hole or even a 1.8mm… That will give you plenty of room for adjustment. Again, after re-drilling the reed hole, smooth the backside.

A tiny burr can cause the shifting problem during tightening.

The Lucky 13 reeds are pretty tough. I recommend using a smooth block of hardwood for the holding surface. Tape the reed down firmly and use a sharp drill bit. This will help eliminate burrs and distortion on the bottom face of the reed.

Regards,

Dave

----------

It's about time I got around to this.

Last Edited by dchurch on Oct 30, 2016 11:51 AM

|

mlefree

787 posts

Oct 31, 2016

8:59 AM

|

Roverharp, one way I've found to mitigate the twisting of a reed with respect to the slot as you tighten the screw is to place a shim in the gap opposite the clockwise side of the reed. If you use the right thickness shim stock, the reed will not only not twist, but it will be properly centered once you've tightened it down.

Also, using brad-point bits and a needle-point center punch help reduce the bit wandering problem. Still, I end up reaming or drilling out the reed plate and reed holes larger than required and shifting the reed around until is in position before I tighten it down. Though I don't yet have his latest set, Richard Sleigh's new reed wrenches allow you to grab the rivet pad and move the reed in any direction. Right now I do it manually under magnification.

Finally, drilling holes leaves a burr or raised area on both sides of the reed plate or reed. In my experience, it's crucial to flatten and smooth the area around the reed plate hole as well as the underside of the rivet pad to achieve optimal zero point in reed curvature. You can do it with a suitably-sized round pin punch or with sandpaper. Not doing so invites leakage that can only be corrected by a kludge like varnish to seal it.

Thanks for the input,

Michelle

----------

SilverWing Leather - Custom leather creations for musicians and other eccentrics.

Last Edited by mlefree on Oct 31, 2016 9:01 AM

|

Post a Message

|